Moisture is the medium of chemical reaction. Absorption of moisture will result in changes of medicine as agglomeration (such as sodium bicarbonate), deliquescence (such as calcium chloride, chloral hydrate), dilution (such as glycerol, lactic acid), mildew (such as dextrose, pepsin), hydroxylation (such as penicillin) and oxidation (such as vitamin C). Such changes will bring difficulties to the preparation of certain medicine or to the accurate controlling of dosage. These changes even cause reduction of drug effect and make some medicine irritant and toxic. Therefore, medicine package has a higher demand for water vapor permeability. Water vapor permeability of medicine package, which can directly influence the stability of medicine quality, is an important property index of package material.

1. Requirements of Standard Testing

In order to strengthen quality control of medicine package material, the State Food and Drug Administration has issued a series of new standards relating to medicine package material that can help package manufacturers produce products in accordance with medicine package requirement and can facilitate medicine enterprises to use the products. Electrolytic analysis method appears in some new standards as the testing method for water vapor permeability testing of film and sheet. Before that, weighting method is used as the only method for water vapor permeability testing of film and sheet in domestic standards. However, in ISO standards, besides weighting method, there are infrared method and electrolytic method, etc.

In YBB00192004 (BOPP/VMCPP Biaxial oriented polypropylene laminated polyethylene/vacuum cast polypropylene) and YBB00202004 (PT/AL/PE), it is clearly required that the testing should be performed using the second method (electrolytic method) of water vapor permeability testing method. The first method –cup method (weighting method) in YBB00092003 is suitable for film and sheet with a water vapor transmission rate of no less than 2g/(m2·24h). Electrolytic method is more suitable for water vapor permeability testing of film, sheet and aluminum foil with minor permeability data for medical use. Some standards point out that water vapor permeability of material should be tested according to standard YBB00092003 without providing specific testing method. However, since all the material to be tested has smaller water vapor permeability, it should be tested using electrolytic method according to the standard.

2. Introduction of Electrolytic Analysis Method

ISO 15106-3 is the widely used standard that is compiled rather comprehensively about electrolytic method for water vapor permeability testing. In the standard, testing principle of electrolytic method is explained as follows: The gas transmission cell is designed in such a way that, with the test specimen inserted, it is divided into a dry chamber and a controlled-humidity chamber. The dry side of the specimen is swept by a flow of dry carrier gas, and water vapor permeating through the specimen from the controlled-humidity chamber is carried by the carrier gas into an electrolytic cell. This cell contains two spiral wire electrodes, coated with a thin layer of phosphorous pentoxide, mounted on the inside wall of a glass capillary. The carrier gas is passed through the capillary where the moisture it holds is quantitatively absorbed by the phosphorous pentoxide and decomposed electrolytically into hydrogen and oxygen by the application of a D.C. voltage of about 70V to the electrodes. The mass of the moisture which permeates through the specimen and is decomposed per unit time is calculated from the electrolytic current required.

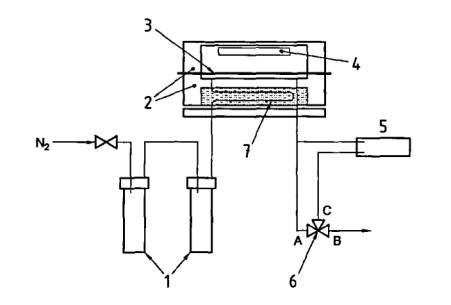

Testing principle of electrolytic method is illustrated in fig.1.

Fig.1 Testing Principle of Electrolytic Method

Note: 1. drying tube (containing desiccant such as molecular sieve)

2. 2-chamber transmission chamber (self controlling temperature liquid contained in it passing through the two chambers)

3. specimen

4. glass fiberboard, dipped in vitriol solution

5. electrolytic cell

6. conversion valve

7. copper tube, used for supplying carrier gas (in the self temperature controlling liquid, gas temperature can be controlled at testing temperature)

Apply D.C voltage to the two electrodes. Moisture in the carrier gas passing through electrolytic cell will be absorbed continuously by the layer of phosphorous pentoxide and then produce phosphoric acid. Phosphoric acid will be electrolyzed into hydrogen and oxygen and form current flow between the electrodes. At the same time, phosphorous pentoxide will be re-generated. Since Electrolyzed current is in direct proportion to the humidity of carrier gas, humidity of carrier gas can be measured through testing electrolyzed current and then calculate the water vapor transmission rate of specimen.

If electrolytic cell is considered as a sensor for the humidity testing of carrier gas, then, both electrolytic method and infrared method are categorized as sensor method of water vapor permeability testing. Generally, when sensor method is used for water vapor permeability testing, the design of transmission chamber and gas pipeline is very similar. The main difference is how to testing the moisture after carrier gas has left testing chamber. Different sensors are based on different testing principles and their working efficiency varies a lot. Therefore periodic calibration of instruments is required, which is similar to the auto gas permeability testing of sensor method.

3. Water Vapor Permeability Tester of Electrolytic Method

Comparing with cup method, the application fields of electrolytic method are smaller. Due to the issue of standard YBB00092003, electrolytic analysis method will become the second method of water vapor permeability testing, which is widely used in our country after cup method.

As the first manufacturer setting foot in package permeability testing field, Labthink has begun to develop corresponding water vapor permeability tester of electrolytic method - TSY-W3 Electrolytic Water Vapor Permeability Tester. At present, this instrument is in the final commissioning period and will enter the market in the second half of the year. We are confident that relying on its excellent property, TSY-W3 Electrolytic Water Vapor Permeability Tester will provide superior service to the customers.